Separated vs Integrated LED Neon Signs: Key Differences Explained | Vasten Lighting

Separated vs Integrated LED Neon Signs: Key Differences Explained

Original article adapted from Wanshiteng Neon, June 13, 2022, Guangdong*

Currently, there are two main technical routes for creating LED neon signs: the separated type and the integrated type. This guide by Vasten Lighting explains their differences, advantages, disadvantages, and how to choose the right solution.

What is a Separated-Type Neon Sign?

The silicone light-diffusing cover and the LED light source are separate components (a light-diffusing silicone strip and an S-shaped LED strip). The process involves:

Light guide silicone strip as shown below

S-shaped LED strip light (as shown)

- Carving a groove into a backing board (often PS board or PVC foam).

- Adhering the S-shaped LED strip inside the groove and soldering wires.

- Pressing the silicone strip into the groove to cover the LEDs.

As shown below

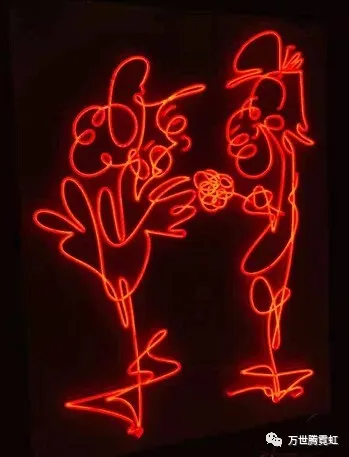

The lighting effect of the separated-type neon sign is also fantastic!

The result offers a neat appearance and strong lighting effects. Explore Vasten custom LED neon signs.

What is an Integrated-Type LED Neon Sign?

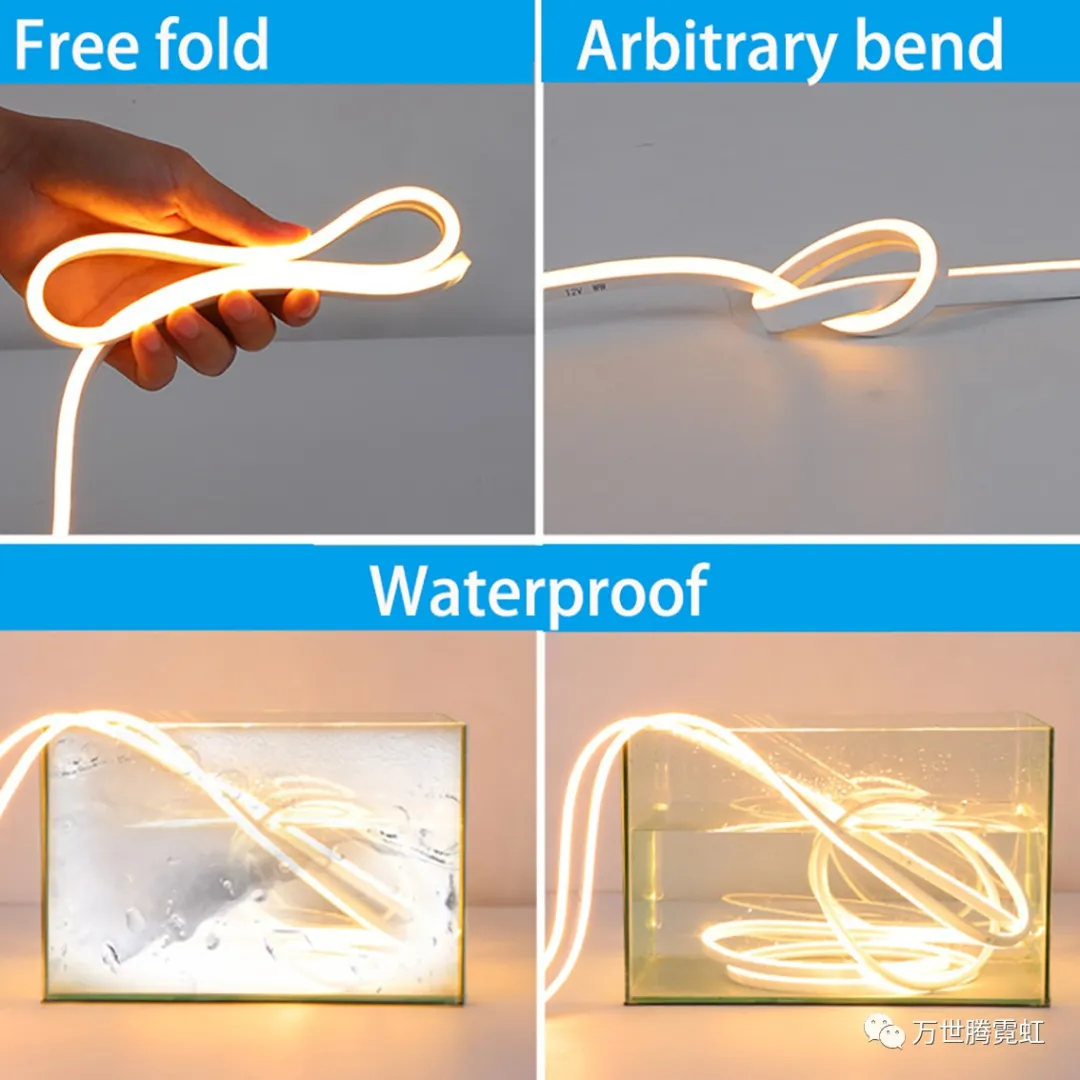

“Integrated” means the light source strip and the silicone light-diffusing tube are one inseparable piece.

The LED light source strip and the silicone are co-extruded from a silicone extrusion machine.

The following picture shows the neon light pasted on the brushed stainless steel surface

Comparison of the Two Types

1. Manufacturing Process

- Separated: Groove the board, insert LED strip, press in silicone. Simple to learn, high production efficiency.

- Integrated: Glue onto board surface, requires higher skill and precision. Lower efficiency.

Conclusion: The separated type is more efficient in production.

2. Materials

- Separated: Uses single-layer PCB (easy to bend). Backing board must be ≥6mm thick.

- Integrated: Uses double-layer PCB (stable). Supports thinner or high-end materials like stainless steel.

Consumer Guidance

Separated Type

Advantages: Lower cost due to efficient production and cheaper raw materials.

Disadvantages:

- Grooved boards are prone to breaking during transport.

- Heat transfers directly to the board, causing warping or even fire risk.

- Silicone strips may fall out, ruining the design.

Integrated Type

Advantages:

- Durability: No deep grooves, stronger backing board.

- Safety: Flame-retardant silicone, better heat dissipation.

- Integrity: Strong adhesion, not easily dislodged.

- 3D Effect: Raised surface mimics traditional glass neon.

- Complex Designs: Enables smaller letters and intricate shapes.

- High-End Finish: Supports premium backboards like brushed stainless steel.

Disadvantage: Higher production cost due to lower efficiency.

Final Analysis

In conclusion: you get what you pay for. The separated type is budget-friendly but less durable and safe. The integrated type costs more but excels in safety, durability, aesthetics, and premium finishes. Consumers should choose based on usage scenarios, budget, and design requirements.

For professional advice and premium options, contact Vasten Lighting — a trusted supplier of LED neon lights and custom LED neon signs.

Post time: Sep-30-2025

With this technique, the co-extruded flexible LED neon strip is adhered to the surface of a backing board or into a shallow groove. This method allows for a wider choice of backing materials, such as aluminum plate, stainless steel plate, PVC board, acrylic sheet, organic glass, etc. The image below shows a neon sign adhered to the surface of brushed stainless steel.

With this technique, the co-extruded flexible LED neon strip is adhered to the surface of a backing board or into a shallow groove. This method allows for a wider choice of backing materials, such as aluminum plate, stainless steel plate, PVC board, acrylic sheet, organic glass, etc. The image below shows a neon sign adhered to the surface of brushed stainless steel.